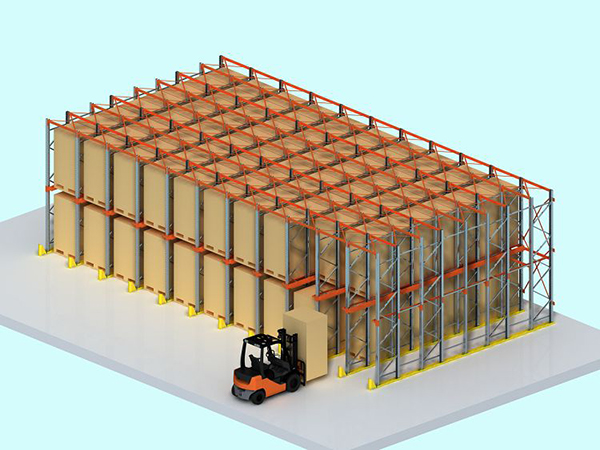

Drive in pallet racks for Industrial Storage

Our drive in pallet racks are good choices for storing large volumes but fewer varieties of goods. It reduces 35%, even more, and utilizes area requirements compare to standard selective pallet racks when having the same pallets storage capability. Drive in need fewer aisles than selective pallet racks, enhancing the utilization of the warehouse area. But in the warehouse daily work,drive in drive thru pallet racks need forklifts to drive directly into the storage rack, subject to more abuse than any other type of warehouse rack.

Advantages of drive in drive through pallet rack:

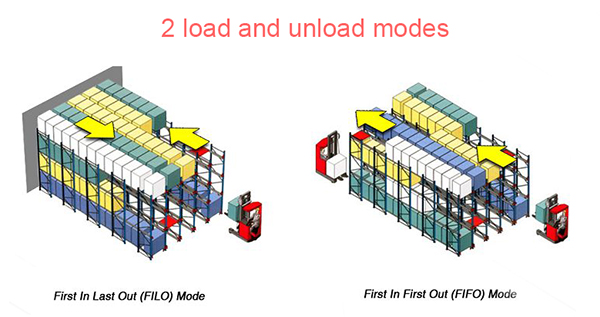

1. (LIFO)Last in first out and(FIFO)First in first out,2 inventory rotate modes for choice.

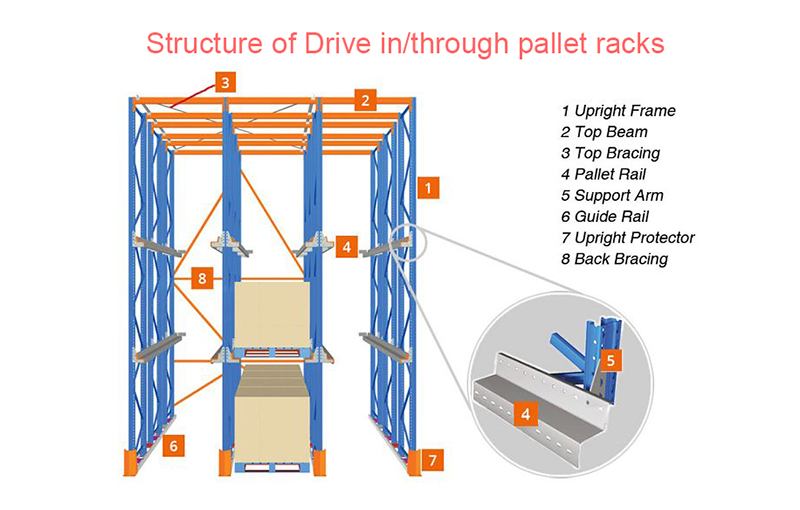

2. Load rails use flared entry design, easier bay access operation.

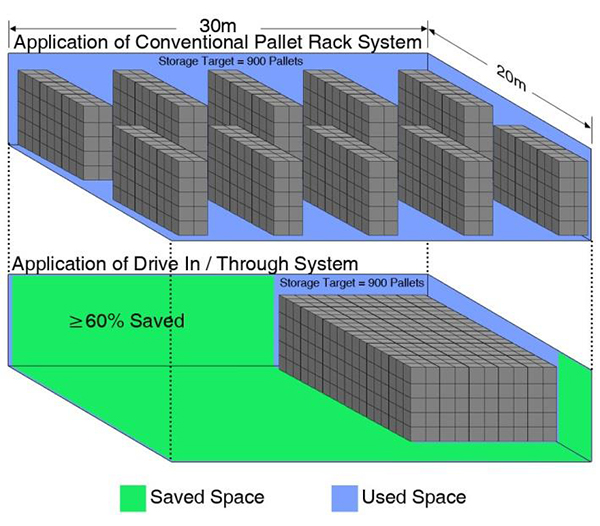

3. Reduce warehouse area need in the same storage capability requirement, saving money compared to other types of pallet rack systems.

4. Lower profile arms increase clearance and decrease possible product damage.

5. Welded rail stops prevent loads pushed off, more safety for warehouse workers and pallet goods.

6. Higher density but less selectivity compare to selective Pallet Racks.

All racks of Drive in drive through racking systems are integrated as one structure, minimizing the waste using spaces.

E.g. 900 pallets storage space comparison (shown as an image)

Conventional selective pallet rack: The whole warehouse is 30×20 sq.m.

Drive-in/Through rack system: Only 40% of the space is 14×18 sq.m.

The drive in drive through racks are very suitable for large-volume storage and pick-up. First-In-Last-Out (FILO) mode and First-In-First-Out (FIFO) mode are optional for different warehouse storage purposes. FILO is suitable for long-term or no-expiration warranty goods, such as electrical products, clothes, shoes, office supplies, tobacco, etc., and the FIFO is usually applied for short-time validation products with pack-to-deliver purposes in manufacture warehousing facilities, such as pharmaceutical products, food, and drinks, etc.

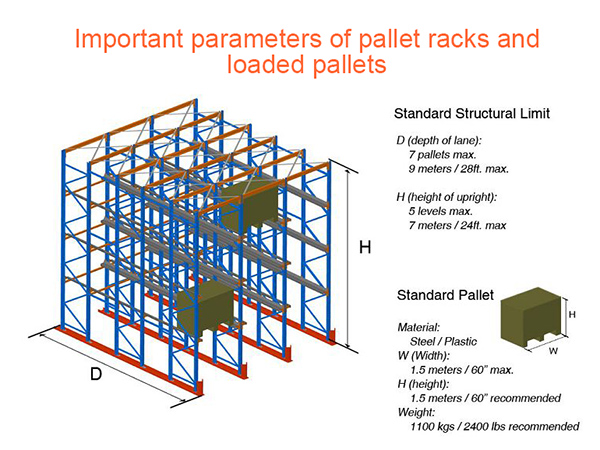

Dimension limited of the drive in drive through pallet rack:

Considering the safety factor of the drive-in & through rack system, the total height should not exceed 5 levels (usually 7 meters / 24ft.), and the depth of the lane should not exceed 7 storage space units (usually 9 meters / 28 ft.), and pallet weight should not exceed 1100 kgs (2400 lbs).

Forklift Dimension

The width, maximum elevation height, and turning radius all affect the rack selection and layout.

As a professional pallet rack system supplier, Spieth Storage has provided many successful Drive in&through racking projects for our customers’ industrial storage needs. Our rack products have pass the certificates such as CE, AS-4084, RMI, etc., just enjoy our one-stop service of pallet rack warehouse building, from design to installation.