factory customized Heavy Duty Pallet Beam Storage System - Drive in Drive through Pallet Racking System – Spieth

factory customized Heavy Duty Pallet Beam Storage System - Drive in Drive through Pallet Racking System – Spieth Detail:

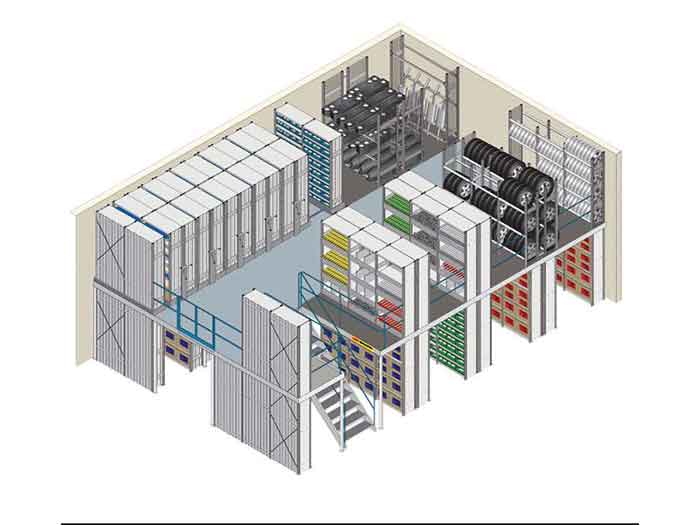

The drive in drive through racking system has a very high-density storage of goods, and it also has a very high requirement for the stability of storage racking, so this storage racking system has much more spare parts when compared with other kinds of warehouse storage racking. The upright frame is connected by accessories to make full use of the rack warehouse space. The components for drive in drive thru pallet racking include upright frame, single stub, double stub, top bracing, horizontal bracing, diagonal bracing, upright protector, rail, and so on.

The drive in drive thru pallet racking is nowadays widely used in all kinds of industries such as cold room and animal husbandry and so on. There is a lot of advantages for drive in drive thru pallet racking. It has a very high-density storage of goods. This kind of storage racking insists FILO system. That is, first in, last out, suitable for the operation of many transportation carts. Based on the elevation height of ordinary forklifts and the conventional scheme of three-story cargo, the effective storage capacity of the warehouse can be increased by more than 100%, compared with the investment cost is controlled and the efficiency is significantly improved.

From the global storage cost calculation, the investment cost can generally be offset by the increased storage capacity benefit within three years. When we use the drive in and drive through racking, it is essential to make research on the system feature for the rack warehouse. For example, how to reach the most effective and largest storage capacity in the warehouse by using different designs of drive in and drive through racking.

The customer needs to pay special attention to the safety of the operator because the forklift needs to drive into the racking passage to pick up the goods. If the drive in drive through racking system is not stable and collapse, it will do harm to the related person. And all goods will be damaged at the same time. This will cause a great loss for the customer. Daily maintenance and maintenance of the storage racks are also reflected in a shelf storage racking factory service priority, the customer’s high-level rack maintenance to ensure efficient storage and safe use of the racks. While we all already know how using drive in drive through racks can help companies improve their economic performance, it’s not enough to pay attention to that, and we need to be aware of how to make better use of drive in drive through racks to maximize economic benefits.

Product detail pictures:

Related Product Guide:

We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for factory customized Heavy Duty Pallet Beam Storage System - Drive in Drive through Pallet Racking System – Spieth , The product will supply to all over the world, such as: azerbaijan , Korea , Islamabad , With many years good service and development, we've a professional international trade sales team. Our products have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.