heavy duty drive in pallet racks wholesale by Spieth Storage

Heavy Duty Drive in pallet rack system provides a low budget and high density storage ability for customers with lower SKU counts. Drive-In pallet rack systems load from the back to the front (First-In Last-Out) as the forklift literally drives into the steel constructure, loads the pallet onto rails and backs out of the rack system. As the system is loaded rear to front, it must it be unloaded front to rear.Heavy Duty Drive in pallet rack system reduce the number of aisles required in a warehouse. It is frequently used in cold storage applications, where the cost of (refrigerated) volume is at its highest and requires the most return on investment (more density).

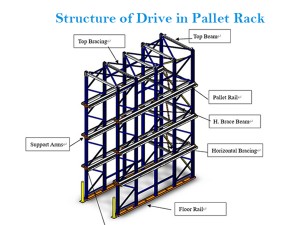

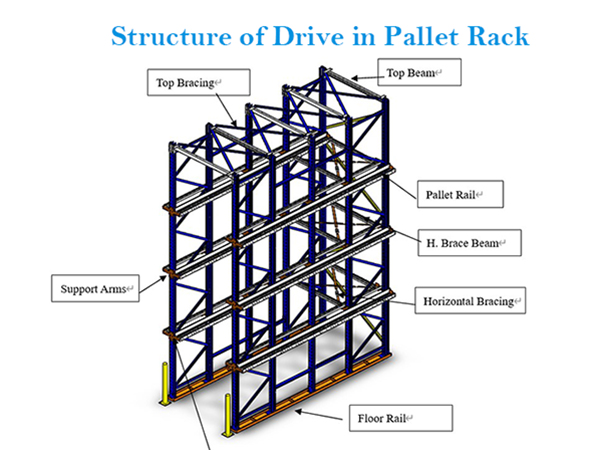

2. PRODUCT STRUCTURE:

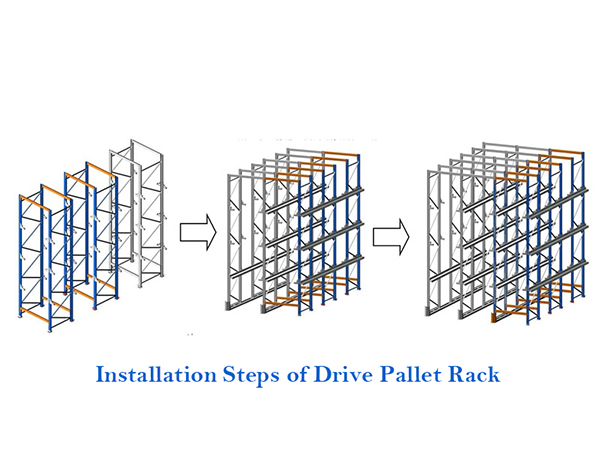

Heavy Duty Drive in pallet rack system is made up of sets of frames and vertical uprights joined together to form inner lanes. Each lane is equipped with support rails on both sides, laid out at different levels, on which pallets are placed. For loading and unloading operations, the forklift truck enters the lanes with the unit load lifted above the rail where it will be placed.

Heavy Duty Drive in pallet rack system allows as many SKUs as loading lanes. Depth and height are dependent on the number of pallets to be stored.

3. Features and Advantages of Heavy Duty Drive in pallet rack system:

>High-density pallet racking

>Ideal for high-volume, low-SKU applications

>Lane depth 10+ pallets deep

>LIFO stock rotation — drive-in

>FIFO stock rotation — drive-thru