Personlized Products Pallet Corner Protector - Drive thru Pallet Racking System – Spieth

Personlized Products Pallet Corner Protector - Drive thru Pallet Racking System – Spieth Detail:

The drive thru pallet racking system can be divided into the single arrow and double array storage racking according to the direction of picking up goods. For the single array racking ( against the wall), the total depth should be controlled within 6 pallet positions. For the double side, array drive thru pallet racking system, the total depth of drive thru pallet racking system should be controlled within 12 pallet positions. This can enhance the efficiency and stability of the forklift to pick up the goods.

This kind of warehouse storage racking has a very weak point instability. In light of this, the height should be controlled, normally the height is not more than 10 meters.Drive thru pallet racking is an entire storage rack that is not divided by channels and is continuous, and on the support rails (bull leg beams), pallets are stored in a depth direction, one by one, which makes high-density storage possible.

The drive thru pallet racking systems are suitable for small varieties, large quantities of goods storage often used to store a large number of the same type of goods, the use of space is higher, suitable for the food industry, chemical industry, garment industry, cold storage, and other storage space costs are higher occasions, its unit site storage costs are relatively low.

It is essential to add some types of equipment and choose a larger specification to increase the stability of warehouse storage racking. The goods in the pallet shouldn’t be too heavy, the loading capacity is not more than 1500 kg per pallet. The pallet span should not be greater than 1.5 meters.

When using the drive thru pallet racking, it is the most effective way to have the highest efficiency by loading goods from one side, but unloading goods from another side. What we need to pay attention to is how to make better use of incoming shelves to maximize economic benefits.

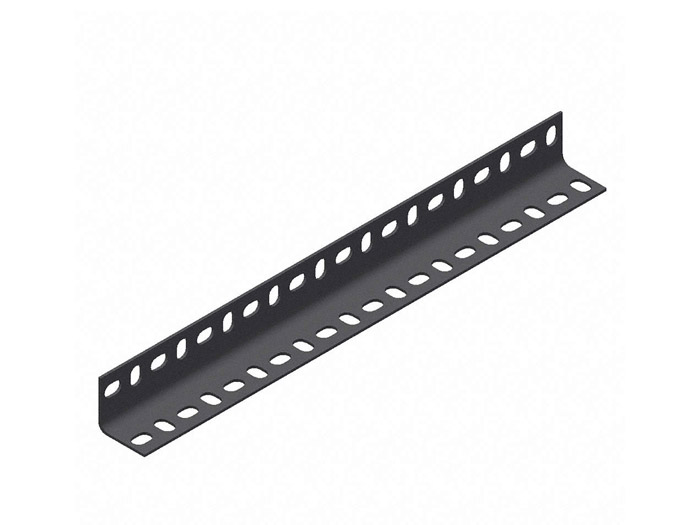

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Personlized Products Pallet Corner Protector - Drive thru Pallet Racking System – Spieth , The product will supply to all over the world, such as: Curacao , Netherlands , Comoros , All our staffs believe that: Quality builds today and service creates future. We know that good quality and the best service are the only way for us to achieve our customers and to achieve ourselves too. We welcome customers all over the word to contact us for future business relationships. Our products are the best. Once Selected, Perfect Forever!

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.